What Poor Leadership is Really Costing Your Mining Operation

Posted By:

In mining and heavy industry, we often track tonnes moved, ounces produced, and dollars earned. But one of the biggest cost drivers rarely shows up on a report: poor leadership.

Leadership development is sometimes dismissed as “soft skills”, but the evidence says otherwise. From plant reliability to workforce retention, from safety outcomes to profitability, the impact of poor leadership in mining is measurable (and costly).

Let’s take a walk through a realistic mining scenario to bring this into focus.

The Business Case for Leadership Development: A 300,000 oz/yr Open-Pit Gold Mine

Imagine an open-pit gold mine producing 300,000 ounces per year, operating 24/7, 365 days a year. The operation uses six primary digging units and a sizeable haul fleet. The mill processes ore continuously and relies on disciplined maintenance to keep uptime high.

On paper, everything looks solid. But dig a little deeper and the cracks start to show.

What Poor Leadership Looks Like on Site

Here are common signs of weak leadership and disengagement in a mining operation:

- High absenteeism in the haul truck fleet, especially at the start of a shift or roster.

- Maintenance rework cost piling up due to incomplete or poor-quality jobs

- Safety incidents that disrupt operations and drive up WSIB premiums.

- Low morale and high turnover among skilled trades, operators and supervisors.

- Inexperienced new hires stepping into complex roles too quickly due to lack of retention.

- Supervisors 'putting out fires' all day instead of coaching or developing their teams.

These symptoms may seem like part of doing business, but they all trace back to the quality of leadership at all levels.

Quantifying the Cost of Poor Leadership

Let’s translate those leadership gaps into operational costs.

1. Maintenance Rework

- Assume 5% of work orders (~250 annually) require rework due to poor execution, skipped services or poor planning.

- Average cost per rework: $1,500 (labour, parts).

- Direct cost: $375,000/year.

But rework doesn’t just cost in labour and parts. It affects availability.

- Estimated cost per downtime hour of our plant downtime is $115,000/hr.

(Assume 12hrs/year (1 hour per month) of rework caused DT) - Estimated cost per downtime hour of a CAT 6060 shovel is $20,000 to $45,000/hr (Assume -1% availability – 88hrs on fleet of 6 shovels)

- Even if only 25% of this impacts gold production (due to bottlenecks or missed shifts)

- At $3,000/oz: $1.125 million/year in value loss.

Total impact: $1.5 million/year.

Better supervision, coaching, and planning could reduce this by half or more.

2. Absenteeism in Mining Operations

- Assume 2% daily absenteeism in a 60-operator haul fleet = ~1.2 trucks offline/day.

- Lost productivity: ~6,000 tonnes/day.

- Annual impact: ~2.2 million tonnes of ore/waste delayed.

- If 10% of this impacts production, the gold loss (0.6g/t grade) = 420 oz.

- At $3,000/oz: $1.26 million/year in lost value.

Operator absenteeism typically affects the first day or two of the rotation. They are often considered no shows with little to no warning. FIFO mines will struggle as it is difficult to use OT to compensate. They will often maintain higher operator numbers to make-up predicted shortfall or use contractors to fill the gap.

- Maintaining staffing levels through overtime will increase labour costs by about $1,000,000 a year (1.2 operators * 24 hours per day * $60/hour at time and a half) (2*24*60*1.5*365= $946,080)

Total impact: $2.2 million/year.

3. Safety Incidents and WSIB Costs

- An average lost-time incident costs $60,000 to $100,000 in WSIB.

- Assume 5 incidents per year = $300,000 to 500,000+ in direct costs, not counting morale or reputational impacts.

Companies with strong safety leadership cut these rates by 60-70%.

However, WSIB costs are a small part of the true cost of an HSE incident. The 6-hour investigation cannot be made up with overtime. At 2,000 tph, each incident could be worth up to $139,000 in lost revenue at $3,000 gold.

6 hours x 2000 tonnes/5 (4:1 strip ratio) x (0.6g/t /31.1) x $3,000/oz = $138,906

I am being very conservative estimating the cost of safety/LTIs/equipment damage to a mining operation. Is this something that you are living with?

4. Turnover and Retention

- Replacing an experienced tradesperson/operator or supervisor costs $50,000+ (recruiting, onboarding, productivity loss).

- If 15 key roles turn over per year = $750,000 / year.

- This doesn’t include the cost of errors by under-trained replacements, or the time spent by senior people covering gaps.

In a stable operation, strong leaders focus on both technical and people skills. Providing skills training to a disengaged or demotivated worker often yields minimal benefit — they may not apply or retain what they’ve learned. But an engaged workforce, led by supportive supervisors, will actively seek out and absorb technical training as part of their career development. The return on training investment is far higher when engagement is strong.

5. Overall Productivity Drag

- Studies show poor leadership can cost 10-15% in overall productivity.

- On a $300M revenue operation, that’s $30-45 million in unrealized potential.

|

Typical Productivity Gaps |

Impact Scope |

Typical Cost Range |

|

Planning discipline |

Productivity, crew efficiency |

$90K – $4M/year |

|

Handover discipline |

Duplication, delays, missteps |

$30K – $1.6M/year |

|

Tool/material readiness |

Idle time, delays, frustration |

$50K – $130K/year |

|

OT due to poor planning |

Labor cost bloat, fatigue |

$100K – $140K/year |

|

Delayed decisions |

Lost production, risk magnifier |

$500K – $1.4M/year |

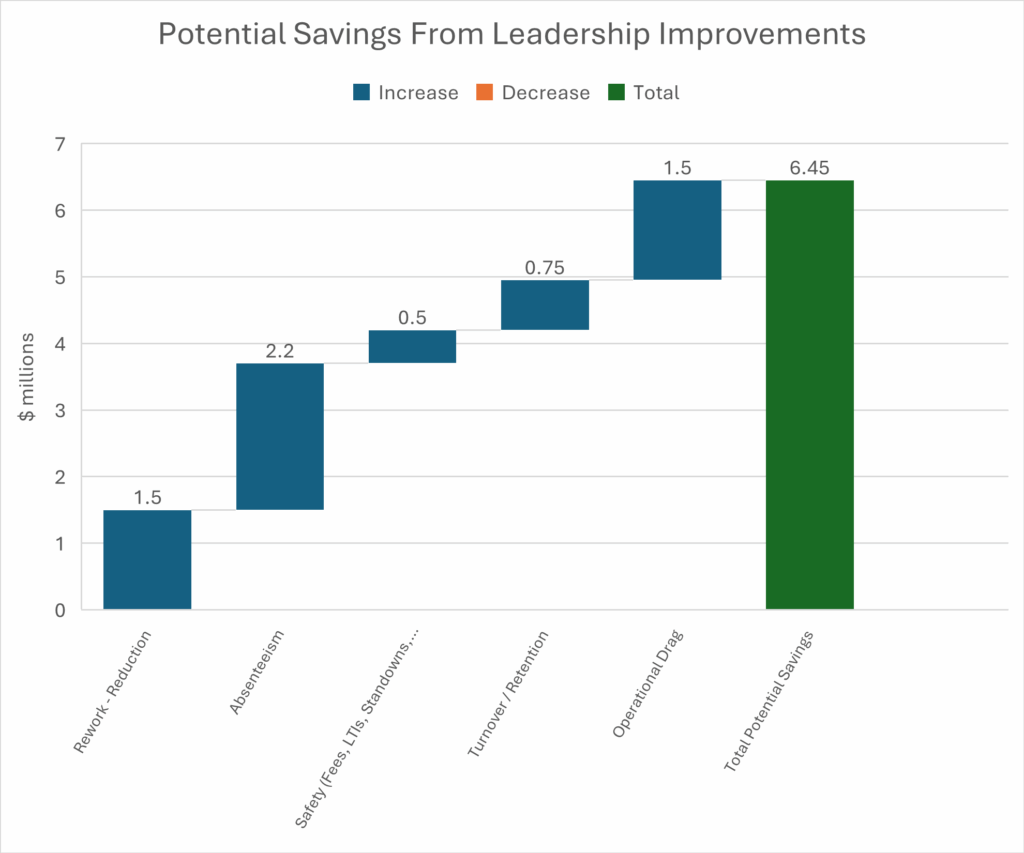

Summary Table: Leadership-Driven Savings Potential

What Great Leadership Looks Like

In high-performing sites, you see something different:

- Frontline supervisors who coach instead of firefight.

- Planners who can rely on teams to execute work right the first time.

- Operators who take ownership and show up ready.

- Fewer surprises in the field.

- Safety conversations that are proactive, not punitive.

Leadership Development Isn’t a Cost — It’s a Lever

When organizations invest in frontline leadership development, the ripple effects are massive. Engagement rises. Retention improves. Safety stabilizes. And the business becomes easier to run.

Leadership is not about charisma or title — it’s about behaviors, decisions, and accountability. And those can be taught.

If you see signs like high rework, low morale, rising turnover, or absenteeism, your problem may not be people. It may be leadership. And the good news is: that’s fixable.

How Outliers Can Help

At Outliers Mining Solutions, we believe that operational excellence starts with leadership. We help mining and industrial clients build high-performance teams by developing all three critical dimensions of capability: Leadership, Technical, and Transactional.

Our approach is hands-on. We assemble experienced professionals — people who’ve led in the field — to train, coach, and mentor your supervisors, superintendents, and managers. Whether you’re working to reduce downtime, improve morale, or close the skills gap, we bring structure, support, and momentum to your leadership development journey.

If you’re seeing signs of rework, turnover, or disengagement, your frontline leadership might be the root cause. Let’s talk about how we can help.

- https://www.gallup.com/workplace/247391/fixable-problem-costs-businesses-trillion.aspx#:~:text=The%20cost%20of%20replacing%20an,to%20%242.6%20million%20per%20year

- https://www.gallup.com/workplace/236927/employee-engagement-drives-growth.aspx#:~:text=%2A%2081,in%20profitability

Read This Next: Mining Talent: Should You Hire All-Stars or Develop Them from Within?

Connect with an Outlier

Subscribe to our monthly newsletter!

All Rights Reserved