Outliers Mining Solutions Time Usage Model Assists Mining and Processing

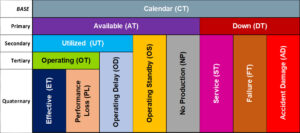

Outliers Mining Solutions promotes a Time Usage Model (TUM) equally applicable to fixed and mobile assets operating on the surface or underground. The primary categorization is whether an asset is “available” and able to perform its intended function or it is “down.” Secondary and tertiary time categorizations are further segmented to provide time usage detail for specific activities or conditions. Lower level time categories must be clearly defined and amenable to data capture.

Oftentimes, standard TUMs are used for their function but lack the appropriate capability to be used in useful and meaningful ways. For example, GMG’s STANDARDIZED TIME CLASSIFICATION FRAMEWORK FOR SURFACE MINING* acknowledges that their TUM is “primarily an operations tool that captures overall asset operational time and downtime.” However, their differentiation between scheduled and unscheduled time can confuse actual asset availability, performance, and use.

The Outliers Mining Solutions TUM listed in Figure 1, below, builds around distinct themes and considerations:

Themes:

- Asset-centric – not influenced unduly by people and process

- Simple, unambiguous time categories

- Asset performance metric consistency and simplicity – a single formula for each and the primary metrics calculated using calendar hours as the denominator

Considerations:

- Time sub-categories are clearly defined and amenable to data capture

- The TUM does not differentiate between “scheduled versus unscheduled” and “opportune versus required” maintenance

- Standard measures for collaboration and reporting

- Effective asset performance measurement is fundamental to operational improvement

Figure 1 Time Usage Model

Asset performance metrics inherent to the model include Calendar time (CT) as the BASE (denominator):

| Time Catagory | Performance Measure | Formula |

|---|---|---|

| Available (AT) | Availability | AT / CT = (CT-DT) / CT = (UT+OS+NP) / CT |

| Utilized (UT) | Utilization | UT / CT = (CT-DT-OS-NP) / CT |

| Operating (OT) | Effective Utilization | OT / CT = (CT-DT-OS-NP-OD) / CT |

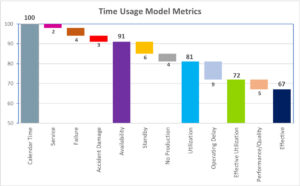

The waterfall chart example below depicts how the Availability, Utilization, and Effective Utilization metrics are arrived at from the calendar time base. The numbers on the bars represent the percentage of calendar time and not hours.

When reading these TUM charts, it is important to consider the following high-level definitions for the 13 categories of the Outliers TUM.

| Description | Code | Definition | Level |

|---|---|---|---|

| Calendar | CT | Specific period – day, week, month, or year | Base |

| Available | AT | Capable of production | Primary |

| Down | DT | Incapable of production due to failure, service, or damage | Primary |

| Utilized | UT | Operating or subject to a delay | Secondary |

| Standby | OS | Available but not utilized due to management decision or external factors | Secondary |

| No Production | NP | May, or may not, be available but not operating due to no market demand, not being required to meet production plan, statutory holidays with no operation, operational shutdowns resulting from force majeure (extreme environmental events, site power interruptions, etc.), equipment assembly, mobilization, and demobilization, etc. | Secondary |

| Service | ST | Voluntarily withdrawn from operation for maintenance – PM’s, planned component replacement, instrument calibration, etc. | Secondary |

| Failure | FT | Out of service due to failure – unable to perform the primary function | Secondary |

| Accident Damage | AD | Out of service due to accident damage | Secondary |

| Operating | OT | Doing productive work and performing the primary function | Tertiary |

| Delay | OD | Utilized but not doing productive work – fueling, de-icing, etc. | Tertiary |

| Effective | ET | Operating at Maximum Demonstrated Rate (MDR) in the processing or production of actual tons | Quaternary |

| Performance Loss | PL | Operating at less than the MDR due to sub-optimal fill factor, excessive queuing, slow loading, hauling and dumping, reduced process flows due to asset internal wear, etc. | Quaternary |

While these charts show the usefulness of a well-operated TUM, there are a few considerations to take into account when dealing with any TUM.

The Great Debate – “I want my MTVBF.“

Most miners and process operators have opinions on how metrics are viewed and calculated. There is much focus on the numbers and how “time” events are categorized and reported. Outliers Mining Solutions focuses on simplifying and clearly defining the time categories to create ease and make more accurate data capture. The simplified process looks like: applying standard formulae to the data, analyze, and make decisions based on the trends more than the number itself. With good data, individual numbers are explainable, whether good or bad.

Code Selection Ease

The strength of a well-designed model resides in its ability to host simple, yet effective single-use time codes aligned with one category to minimize confusion and post-processing. Arbitrary time constraints such as “Reason code X > 12 hours” and “Reason X code <12 hours”, which map in different categories but that are also for the same root cause, create challenges in implementation and use, and require judgment, post-processing, and reconciliation afterward.

Simplicity goes a long way – the people selecting these codes often don’t have time to contemplate them in real-time; hence simple non-duplicate codes yield a better result in adoption and data quality.

No Production

Classification of time use plays a huge factor in determining the site’s time usage. For example, the GMG TUM classifies “No Production” under “Unscheduled Time,” so any increase has no impact on availability metrics. Outliers Mining Solutions recognizes that mining is capital intensive, so operations must maximize usage to deliver the required products and return on investment. Thus, the Outliers Mining Solutions TUM includes “No Production” within the primary category of Available (AT). An increase or decrease in “No Production” impacts availability metrics directly, which tends to ensure the requisite focus to minimize “No Production” whenever possible.

Connect with an Outlier

Subscribe to our monthly newsletter!

All Rights Reserved