Increasing Production and Haul Efficiency at Ferrexpo

In 2016 Outliers initiated a work scope with Ferrexpo to improve the productivity and efficiency of load and haul fleet at Poltava and Yerestovo mines. This scope included the deployment of the Outliers Performance Management tools such as the Short Interval Control tool and the rehabilitation and effective use of the Wenco Fleet Management System to deliver improved truck allocation.

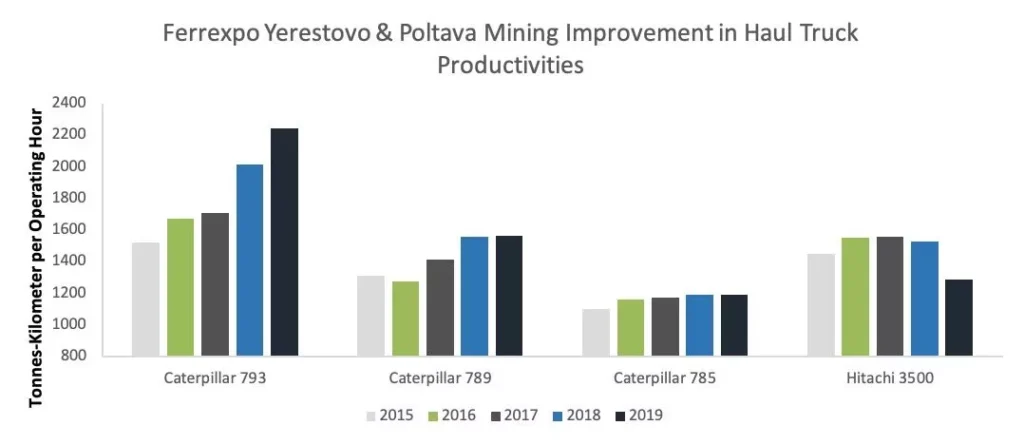

The Outliers team spent time at each mine implementing the Short Interval Control tool and the Value Added Dispatch training, which includes the effective use of automated dispatching. Implementing these programs has allowed both Poltava and Yerestovo mines to reduce wait times at shovels, equating to over 7.6 million tonnes per year improvement. Moreover, automated fuel dispatching has enabled the mine to take less time to schedule fulling and reduce wait times at the fuel bay. The total increase in truck productivity (tonnes-kilometer per hour) was over 22% from 2016 to 2018.

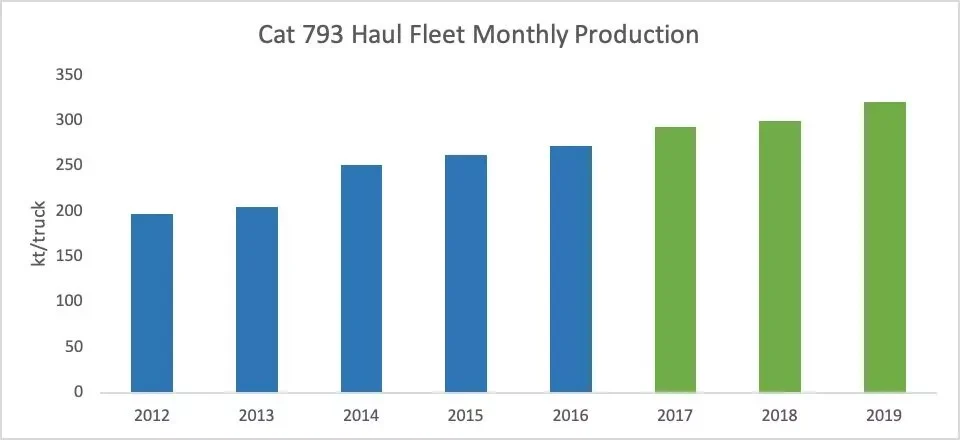

What is more impressive is that not only were higher production rates and movements achieved, but in the last four years, the management has been able to increase material movement with a lower number of deployed trucks. Since 2016, 27 trucks have been decommissioned as a result of the sustained improvements.

These tools are still presently in use at both sites. Their work is a testament to true sustainability achieved through the effective use of technology, coaching, mentoring, and capability building in our people.

Jim North

Acting Chief Executive Officer and Executive Director

The Outliers team spent time at each mine implementing the Short Interval Control tool and the Value Added Dispatch training, which includes the effective use of automated dispatching. Implementing these programs has allowed both Poltava and Yerestovo mines to reduce wait times at shovels, equating to over 7.6 million tonnes per year improvement. Moreover, automated fuel dispatching has enabled the mine to take less time to schedule fulling and reduce wait times at the fuel bay. The total increase in truck productivity (tonnes-kilometer per hour) was over 22% from 2016 to 2018.

What is more impressive is that not only were higher production rates and movements achieved, but in the last four years, the management has been able to increase material movement with a lower number of deployed trucks. Since 2016, 27 trucks have been decommissioned as a result of the sustained improvements.

These tools are still presently in use at both sites. Their work is a testament to true sustainability achieved through the effective use of technology, coaching, mentoring, and capability building in our people.

Jim North

Acting Chief Executive Officer and Executive Director

Outliers operational assessments have always given our clients a quantified and prioritized improvement plan, and in 2020, we proved we can deliver this same service quality remotely. We’ve found they can be executed more quickly, at a lower cost, and with the same high quality.

Connect with an Outlier

Subscribe to our monthly newsletter!

© 2025 Outliers Mining Solutions.

All Rights Reserved