Benefits of a Mining-Focused Business Improvement Training Program

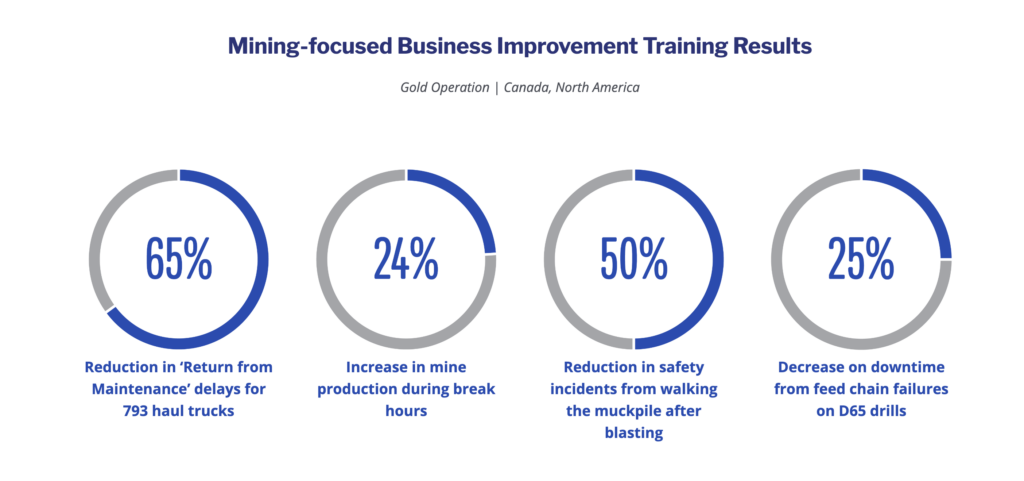

In 2016, Outliers Mining Solutions delivered a Lean Six Sigma Green Belt program at a partner Gold Mining Operation in Canada. The program, conducted over a 6-month period, included two waves of 12 attendees across all aspects of the operation, including mine operation, geology, human resources, finance, and safety departments.

Once executed, the projects realized a total business value of over $68 million, which the site finance department validated. This improvement included a 305 TPOH increase in mill throughput realized through increased secondary crusher power draw. This single project has an annualized value of over $45 million.

These case studies accurately reflect how the OMS Business Improvement Training program effectively enhances mine site’s overall efficiency and productivity. The program is specifically designed to give teachable skills to mining-professionals through hands-on practice and real-world application. Outlier Mining Solutions’ team of experienced mining facilitators are assigned to hand-picked mine site employees to analyze and select areas of improvement. This personalized approach facilitates training that successfully improves site’s safety, production management, and the use of spending. Since the structure of the program provides solutions to active problems, results are seen immediately.

The only requirement for success in the program is for the trainee to be motivated and passionate about improving their work. The OMS Lean Six Sigma program is an excellent development opportunity for young professionals, including Engineers, Geologists and those in maintenance and reliability roles. Some of the most successful Green Belt trainees are former equipment operators who work as supervisors in mine operations or maintenance. Any person in any role, who would benefit from improved project management skills, stakeholder engagement, communication, and root cause analysis will benefit from this training. Upon successful completion of the program, trainees will be accredited Lean Six Sigma Green Belts.

Trainees in the program will leave the first week of training with a chartered project that has a validated business case tied to a real increase in revenue or cost savings. They will begin working on their project straight away with a goal of implementing improvements within 12 weeks. Our experienced Lean Six Sigma Black Belts guide and mentor the trainees as they complete their improvement projects.

Once executed, the projects realized a total business value of over $68 million, which the site finance department validated. This improvement included a 305 TPOH increase in mill throughput realized through increased secondary crusher power draw. This single project has an annualized value of over $45 million.

These case studies accurately reflect how the OMS Business Improvement Training program effectively enhances mine site’s overall efficiency and productivity. The program is specifically designed to give teachable skills to mining-professionals through hands-on practice and real-world application. Outlier Mining Solutions’ team of experienced mining facilitators are assigned to hand-picked mine site employees to analyze and select areas of improvement. This personalized approach facilitates training that successfully improves site’s safety, production management, and the use of spending. Since the structure of the program provides solutions to active problems, results are seen immediately.

Who is the Business Improvement Training Program designed for?

The only requirement for success in the program is for the trainee to be motivated and passionate about improving their work. The OMS Lean Six Sigma program is an excellent development opportunity for young professionals, including Engineers, Geologists and those in maintenance and reliability roles. Some of the most successful Green Belt trainees are former equipment operators who work as supervisors in mine operations or maintenance. Any person in any role, who would benefit from improved project management skills, stakeholder engagement, communication, and root cause analysis will benefit from this training. Upon successful completion of the program, trainees will be accredited Lean Six Sigma Green Belts.

What happens during the training?

Trainees in the program will leave the first week of training with a chartered project that has a validated business case tied to a real increase in revenue or cost savings. They will begin working on their project straight away with a goal of implementing improvements within 12 weeks. Our experienced Lean Six Sigma Black Belts guide and mentor the trainees as they complete their improvement projects.

The OMS Business Improvement Training offers this Lean Six Sigma Business Improvement training to assist in the improvement of mine sites everywhere. Download the guide below to learn more about Business Improvement Training and next steps to being a part of this program.

Connect with an Outlier

Subscribe to our monthly newsletter!

© 2025 Outliers.

All Rights Reserved