Short Interval Control in Open Pit Mining

Posted By:

Effective short interval control allows mine operations to detect issues impacting mine production in real-time so corrective actions can be taken within the shift rather than waiting for end of shift reports to evaluate performance. Short Interval Control should use production data to visualize the performance of the mining fleet in real-time with actionable information for supervisors, dispatchers and operators.

There are a few things that Outliers believes to be important in regard to maximizing the value of short interval control.

1. Short Interval Control should determine the daily potential of the mine based on available resources and the production bottleneck.

The default excuse of poor equipment availability as the reason for not achieving production targets must be removed. The focus of the mine operations teams should be to maximize the performance of the equipment available to them in a given shift while complying with the mine plan. The best Short Interval Control tools dynamically adjust the target for the shift based on what resources are available.

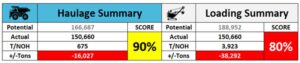

It is also critical to understand the production bottleneck for the shift to correctly prioritize actions. Knowing in real-time if the mine is over or under trucked is the first step in evaluating levers to maximize production in the shift.

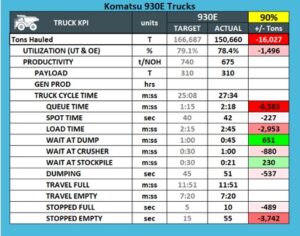

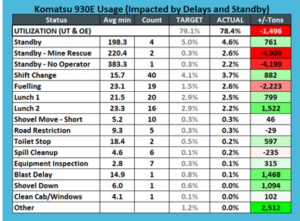

2. Short Interval Control quantifies the gains and losses for each utilization and productivity driver to allow for prioritizing actions and effort.

It can be difficult to contextualize how important seconds and minutes are in the mining process. Telling a supervisor that spot time at a shovel is 10 seconds over target may seem like a small issue while managing the overall shift. However once quantified into how many tonnes or BCMs have been lost it creates urgency and action to close the performance gap.

The best Short Interval Control tools compare each utilization and productivity driver against a target and quantifies the production tonnes or BCMs lost by failing to meet the target. This gives the mining team a prioritized list of areas to investigate to maximize production in the shift. The traffic light system also immediately focuses supervisors and dispatchers on the areas requiring investigation and corrective action.

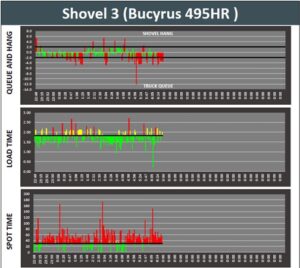

3. Short Interval Control visualizes cycle-to-cycle trends allowing fast detection of changing conditions & performance.

Evaluating shift performance at the end of shift or even on 3 or 4-hour intervals is too long a period. Short Interval Control should provide the ability to detect, in real-time, any change in performance. Trending productivity KPIs on a cycle to cycle basis also allows quick evaluation if corrective actions have had a positive impact on the targeted KPI.

The most important KPIs for trending are the components of loading unit productivity (load, spot, hang, payload), drill productivity (drilling, propel, level, idle, depth) and interactions at dump locations (queue, spot, dumping).

Short Interval Control should be the one-stop tool for Mine Operations to manage and maximize their shift. Having real-time detailed information on the performance of the mine that is quantified & prioritized allows for improved alignment across the execution team.

Connect with an Outlier

Subscribe to our monthly newsletter!

All Rights Reserved