Short Interval Control Solution for Efficient Mining Organizations

Maximize the efficiency of your mining organization and increase the productivity of your fleet with Outliers’ Short Interval Control Solution. Built on a framework of Short Interval Control (SIC), give your organization the power of a detailed scenario playbook for operations and dispatch, complete with dispatcher and equipment operator scorecards and a visual management process.

The Outliers’ Difference

A Tool for the Front-Line Team of Supervisors and Dispatchers

Although Outliers Short Interval Control is often viewed live by superintendents and managers, they are not the audience. Outliers’ tools are designed for supervisors and dispatchers to provide full transparency in real time on the performance of their shift and where to take action.

Improvement Targets

Targets designed to stretch performance and drive continuous improvement, not those in the mine plan which must be achieved.

Real-Time FMS Integration

Harness the power of real-time data with SIC and scorecard tools directly integrated with your fleet management system.

Flexible Target-Setting Tools

Flexible, user-friendly, and web-based — derive and configure your targets.

Lost Tonnes/Lost BCMs Approach

Target the production drivers with the maximum impact on productivity and utilisation with gains and losses quantified in lost tonnes (or BCMs).

"The power of their Short Interval Control tool is that it spans technology and human behavior and during deployment leverages Outliers' expertise in coaching and training dispatchers and field supervisors providing a winning combination that maximizes equipment productivity. I highly recommend OMS and their Short Interval Control tool."

– Chuck Hennessey, Vice President Canadian Operations, Argonaut Gold

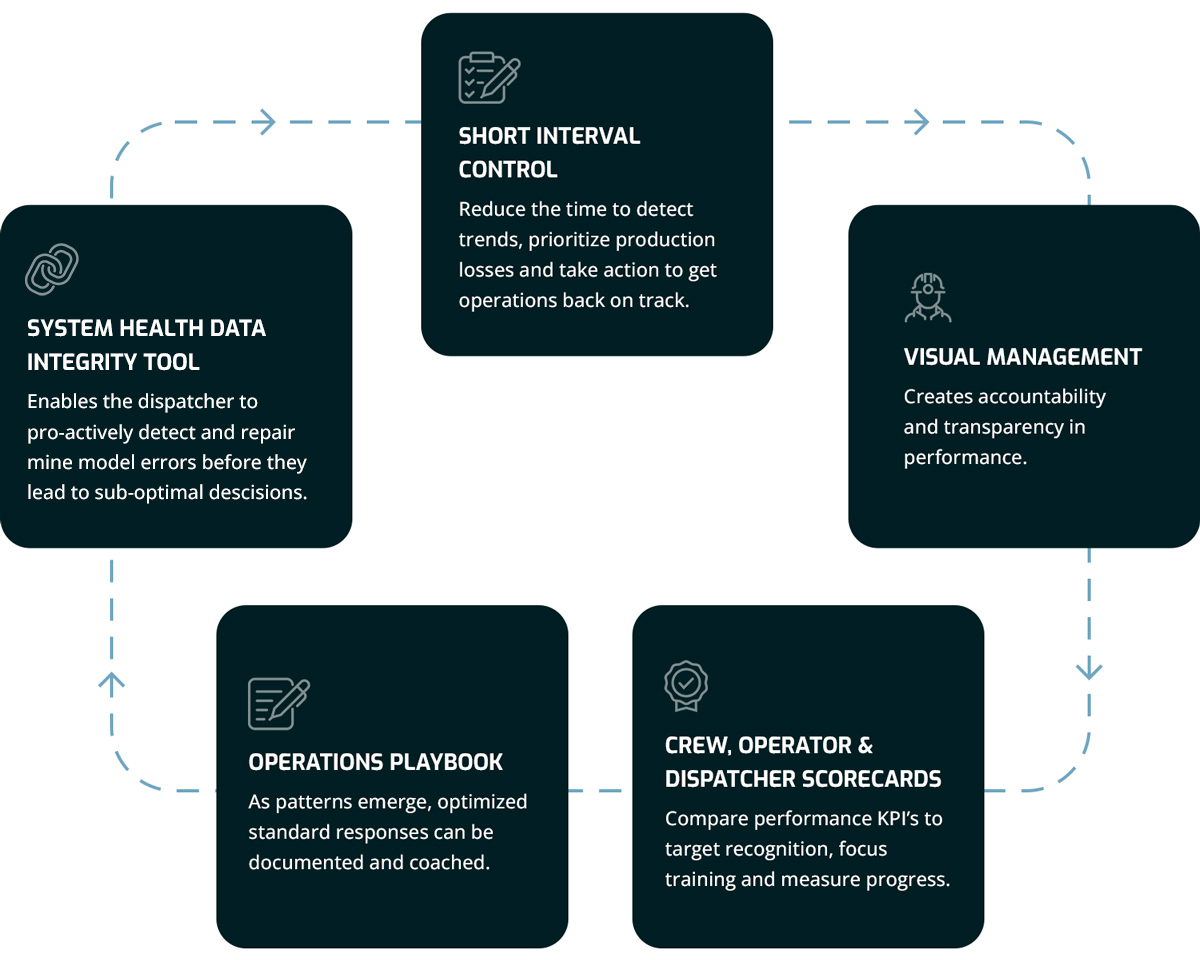

What Is Included

Within our Short Interval Control Solution, the elements work together to create and reinforce a positive feedback loop, improving decision making time and quality.

How It Works

Identify

The dispatcher, blend coordinator or team leader identifies a mine scenario requiring a response, based on pre-determined triggers.

Consult

Observations are reported to the response team, who communicates to stakeholders.

Execute

The response team executes actions from the response plan, communicated positive outcomes of executed actions team-wide.

Analyze

The impact of the response is assessed through determined KPIs within the SIC Solution, communicated results in the visual management process.

"We implemented the Outliers SIC in 2020 in conjunction with in-person training for the dispatchers and saw almost immediate gains that are still sustained three years later. After having implemented the SIC toolkit at two operations with different fleet management systems I can say it is the best way I’ve seen to effectively get the promised gains from FMS."

– Hubert Schimann, Mine Manager, Centerra Gold