Getting The Most Out of SAP

Posted By:

SAP by far is one of the most powerful systems and tools out there to manage your mine. The issue is most never really get proper training or guidance on how to use it effectively.

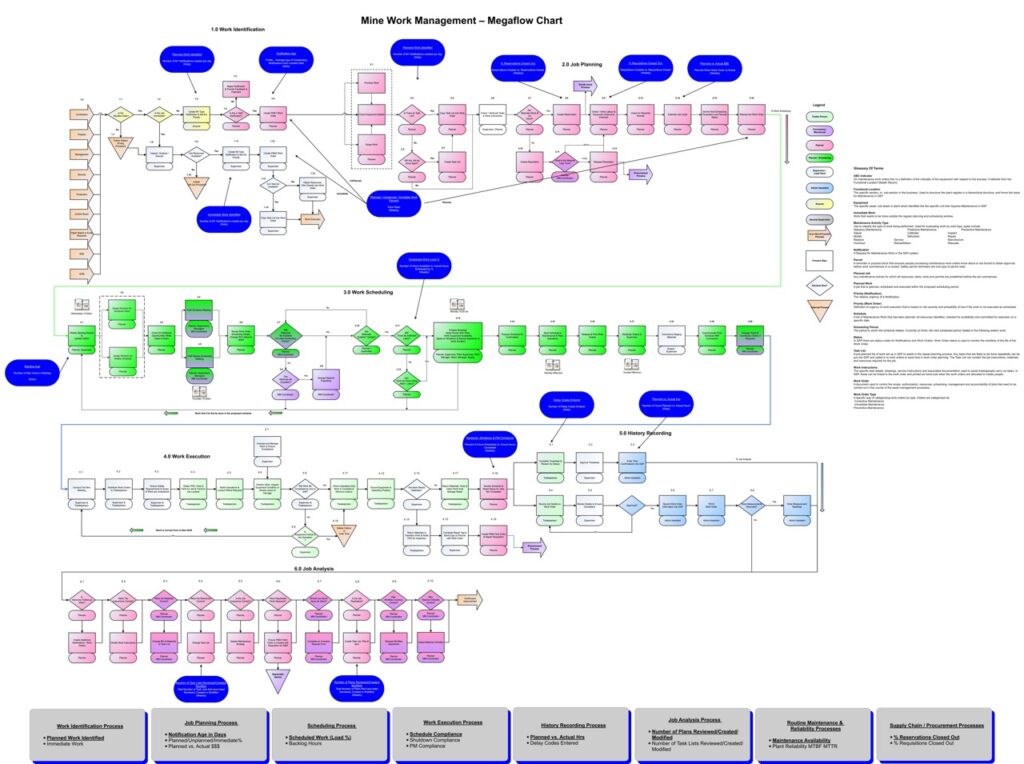

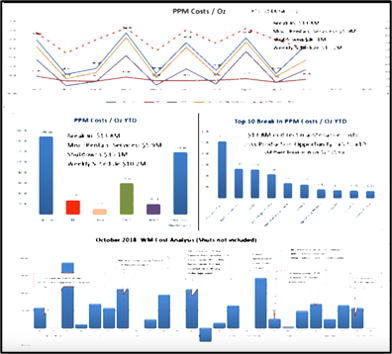

Maintenance at mine sites accounts for 30-50% of operating costs, it is also one of the main reasons for not achieving production targets. So there are 2 critical pieces of information required to improve performance. Quality Equipment Downtime data pulled from an FMS (Fleet Management System) or from a Delay Account System for fixed plant and quality data from your CMMS.

A few years back when I was living in Australia, I created a short presentation called “Getting the most out of SAP”. I was shocked by how little some of the reports and tools were being used in SAP to effectively manage the business. Folks understood it from a transactional perspective but were clueless as to how it could be used to effectively manage all maintenance, material management and finance activities. drive real improvement.

I was extremely lucky early in my career to be part of a pilot implementation of SAP PM and be part of the implementation team as the site maintenance lead. It allowed me to learn about configuration, master data design and participate in integration design and testing with all the other modules (MM, FI/CO, HR, and Projects). I have since participated in another implementation as a Maintenance Manager and 2 full re-implementations of SAP (full process design). I have seen the same challenges in other systems such as Maximo and Pronto.

By far the biggest pitfall I found was a lack of understanding business needs by the implementation teams and what life as a user really is like. This is then reflected in the training delivered during initial implementation where the focus is on the “How to” and little time is put into the “Why”.

I have always prided myself as being a hardcore superuser of SAP PM, MM, FI/CO with a very strong understanding of how the data is linked up and how it links back to business processes, behaviours and most importantly asset performance.

Getting the most out of your SAP was my way of unscrambling the complexity of SAP for folks. It is like the “Matrix.” Once you see what is possible, you start realizing how underutilized SAP is. SAP can be used to review planned work performance, preventive maintenance effectiveness and identify improvement opportunities (Process, System and Equipment). A simple and practical approach can be used to show how SAP can be used to re-enforce good behaviour and discourage poor practices. Through the disciplined use of your CMMS (SAP) data quality, fiscal discipline and process adherence can be measured.

You get what you expect, so set the right expectations and reward the behaviours you are looking for.

Setting yourself up for success:

- Defined Business Processes and Standards

- Clear roles and accountabilities

- Clear expectations by leadership

- A Culture of asking questions and understanding why

- Reward good behaviour and challenge poor behaviours

- Keep it simple!!

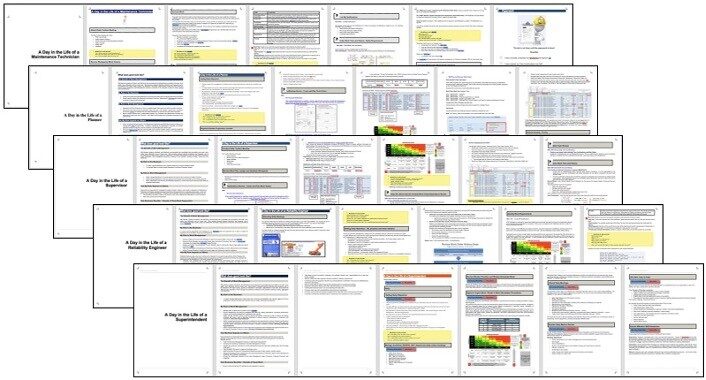

Develop detailed Day in the Life Of (DITLOs)

Tell folks what you want to be done and how they can do it and most importantly why. Over the years I have developed a library of DITLOs to ensure effective role alignment with business processes and needs. They are used in the onboarding process and in learning and development. It is important that we go beyond stating the job ad is the role description. We need to show them what good looks like. They should reflect the MOS – Management Operating System.

SAP has several critical transactions that can provide the majority of what is required to manage the maintenance function.

IH01 is the maintenance data One Stop Shop.

IW28 – Review Outstanding Notifications is the core of the daily work review between maintenance and operations. It allows for a formal approval and work vetting process. It also better manages scheduled break-in work.

IW37n – List Work Order Operation is maintenance equivalent to a live SIC (Short Interval Control) that allows the supervisor to manage the execution of all work types (PMs, Scheduled Corrective, Break-In). It allows them to prepare for upcoming work, and understand work order material and labour requirements. They will understand cross-trade and cross-departmental collaborative activities. They can identify work that has been completed by the tradesperson and follow up. Cost awareness is also incorporated in this report. It is also that report that the Work Management KPIs can be calculated.

As a manager, I had 2 reports that I ran every day that allowed me to understand the good and the bad of the last few days and critical work that was up and coming. I typically knew the answer to the question I was going to ask. It allowed me to provide better coaching and call bullshit when required. It is also our job to ensure we keep our people accountable for quality data. Garbage in equals garbage out. All these expectations are built into the DITLOs and the tools we have developed.

Many managers I have worked with have been intimidated by SAP and refuse to take the time to learn or ask for help. It is like driving at night without your headlights on!! Too stubborn to ask where the light switch is.

I haven’t even discussed the material management reports that allow you to effectively analyze years of data to understand material consumption rates, min/max and re-order points. As senior leaders, it is our job to know and help our teams grow. It is really hard if you lack the skills/knowledge of how to use your most powerful tool at your disposal.

SAP really excels in cost data linked to the activities it was derived from. Learning a bit of advanced MS Excel such as Xlookups, Sumifs, etc… will go a long way in helping analyze large quantities of data.

I am a fan of Standard SAP (Vanilla) with minimum configuration changes, many SAP optimizations are due to folks just not knowing how to get the information they are looking for.

So if you are looking for some help please reach out. There is typically no real need for large teams when implementing these types of improvement. It real all about leadership, clearly stating what the process is and what good likes. If you are the manager (senior leader in maintenance) the effective use of SAP is on you and you alone. Take the time to learn this powerful tool and start getting the benefits out of it.

The Outliers Mining Solutions team prides itself in being nimble and typically takes a swat team approach to every engagement. We have expertise in using SAP as a user (Maintainer, Supervisor, Material Coordinator, Planner, Reliability, Superintendent, Manager) in SAP PM, MM, FI/CO. We also have a good understanding in SAP configuration, Master Data and Data Standards.

Connect with an Outlier

Subscribe to our monthly newsletter!

All Rights Reserved