Using Standardization to Drive Mining Performance

The environment of a mine operation can be challenging because it is unpredictable and dynamic. Standardization of processes within a mining operation can provide stability, consistency and predictability.

Standardization is a practice that is well-known and often undervalued. It is the designing of systems and processes to ensure consistent execution of activities with the intended result of consistent outputs. By following a standard approach, variation is greatly reduced. This leads to a more efficient, stable and predictable process. The mining industry hosts countless opportunities to utilize standardization and realize significant value. Here are the top reasons Outliers Mining Solutions makes standardization of processes a core element of our engagements at client sites.

Following (Current) Best Practice

Every mining organization strives to ensure that all tasks, activities, and processes are performed most efficiently with the best possible results. Standardization is the pursuit of identifying the best method and ensuring it is carried out as defined. While many users have their way, it is important to identify the best way. In many cases, this incorporates elements of how different users carry out a task. It’s for this reason when implementing standards, an important step is the involvement of users and stakeholders to ensure nothing is overlooked. It should also be pointed out that as external influences evolve (such as other processes, technologies, and requirements), standards should be reviewed and updated.Your Content Goes Here

Facilitates Effective Training

Standardized processes are intuitive and easily understood with limited ability to make errors. Standards are designed in a way that understanding them is clear and concise. Traditional training materials tend to be heavily text-based, which can lead to misinterpretations. Well-designed standards incorporate visuals and other methods to aid in understanding. For example, colour coding is an effective way to deploy standards. Red is associated with something wrong/bad/stop, while green is associated with correct/good/go. By making processes more accessible, an organization can unlock the benefits of a more multi-skilled workforce.

Efficient Decision Making

Given that a process or task is designed in a well-defined way and is clear and concise in its understanding, any decision-making by the user becomes minimal, if required at all. When standardization is not used and decisions are needed, the outcome becomes reliant on the user’s knowledge and experience, producing variable results.

Consistent Practices, Stable Processes, Predictable Outcomes

One of the most praised benefits of standardization is the reduction of variation as a result. This is especially important within the mining industry, as there are so many intertwined processes, each impacting the performance of another. Some organizations are fortunate enough to have experienced workers that know how to complete a task. However, if standardization is not incorporated, chances are how they complete the task will differ. While the “finished product” may be the same, the differing practices introducing unnecessary process variation. Examples of this include the time taken to complete a task or the resources required. A major impact of this is the unpredictability of how long something may take, or how much it may cost you.

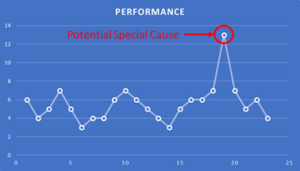

Supports Problem-Solving

One of the most praised benefits of standardization is the reduction of variation as a result. This is especially important within the mining industry, as there are so many intertwined processes, each impacting the performance of another. Some organizations are fortunate enough to have experienced workers that know how to complete a task. However, if standardization is not incorporated, chances are how they complete the task will differ. While the “finished product” may be the same, the differing practices introducing unnecessary process variation. Examples of this include the time taken to complete a task or the resources required. A major impact of this is the unpredictability of how long something may take, or how much it may cost you.

Standardization makes Special cause variation easier to identify

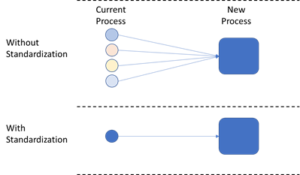

Mechanism for Improvement

Process improvement is realized from the implementation of standardization alone. Additionally, it is utilized as an effective way to set the stage for any improvement work. It allows the improvement effort to focus on one process, rather than trying to improve multiple, slightly different ones. This results in an easier transition for improvement. A major component of the standardization process is gaining an in-depth knowledge of what you’re trying to improve and, while doing this, to identify opportunities. As improvements are identified, they feed into the already established standardization, which aids in the change process.

Changing one process requires less effort than changing multiple

Sustainability of results

Often overlooked for any initiative within the mining industry is the sustainability of the changes made. Standardization supports the sustainability of these initiatives through intuitive design, clear communication, and streamlined processes. Given the large investments made within the mining industry, the return for utilizing a standardization process is high.

One of the major challenges with standardization is implementing it in a way that delivers on its full potential. Due to its simplicity, it is often misunderstood as something easy, just requiring new and/or updated documentation. Effective implementation requires time spent understanding the elements that make up a process, and the involvement of users to fully capture the best practice. Once the best practice is identified, ensuring it is communicated effectively and accepted as the new way is key for success.

When embarking on any new initiative, a key consideration should be the deployment of the standardization process. These steps include collecting information on all current methods, evaluating to identify the best practice, and creating a standardized process that is intuitive and easy to follow. Whether it’s evaluating a mine’s truck haulage performance, asset management practices or any improvement opportunity, considerable gains are made by implementing standardization.

Questions to ask:

- Are your processes unpredictable?

- Do you know what is impacting process variation?

- Are all tasks required?

- Are tasks being completed in the correct, most efficient order?

- What can be done to streamline certain tasks?

- What information is being used to make decisions?

- Are the decisions consistent?

Connect with an Outlier

Subscribe to our monthly newsletter!

All Rights Reserved